Mtuft Mini

A single needle carpet yarn sample machine

Showcase your yarn as high-quality carpet in minutes

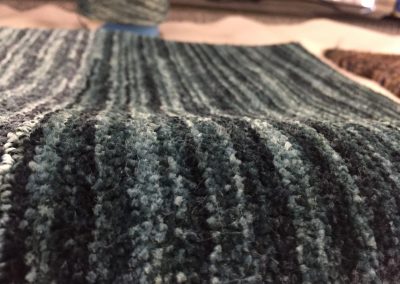

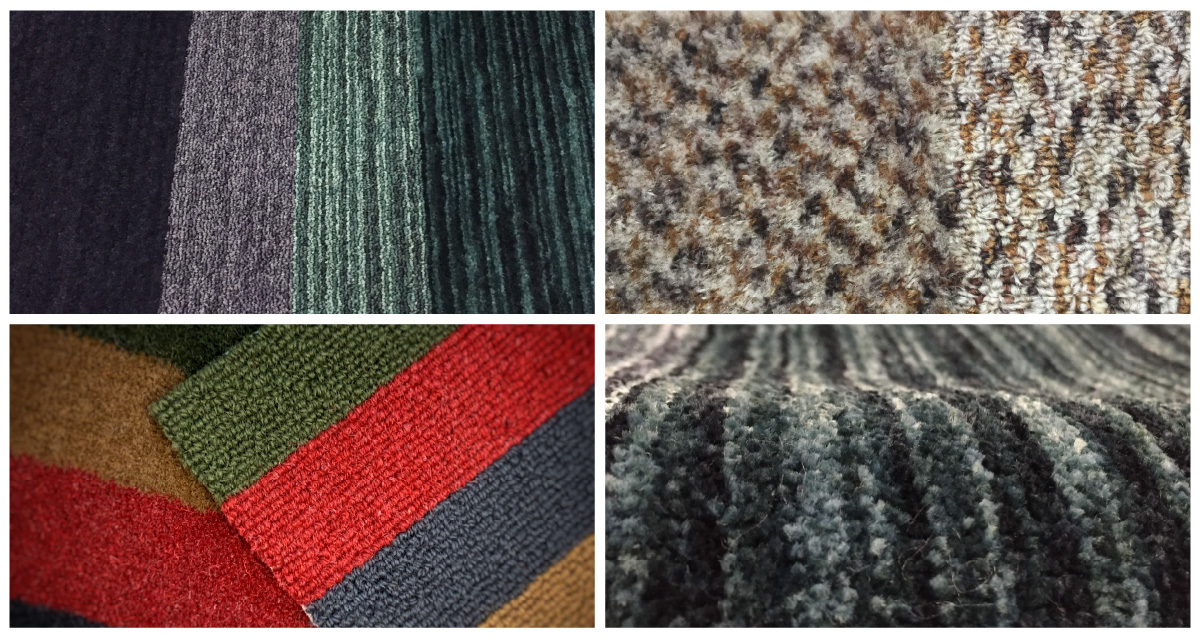

Why showcase your yarn as a pom, package or wrap when you can give your customers a high-quality piece of carpet? The Mtuft Mini enables you to turn a single package of yarn into a carpet sample. Its versatility means it can be used for quality control, testing and development.

Features:

- Powerful software to control gauge (1/16” to 1/4”), stitch rate (10 – 80 stitches / 10 cm) and variable pile heights (up to 75mm)

- Software controlled cut or loop pile

- Maximum product width is 500mm

- Polypropylene backing 600mm wide

Yarn, as it is, cannot speak. But in the form of carpet, its value in terms of touch and sheen is more prominent.

Yarn manufacturer, India

Benefits

The Mtuft Mini enables you to turn a single package of yarn into a carpet sample.

- Quickly present yarn as a piece of carpet (in conjunction with the backing press)

- Reduce the likelihood of faulty yarn being sent to your customer

- Software driven with few mechanical adjustments

- Once set up, the Mini can run unattended

- Single needle and single bobbin of yarn

- Small machine , requiring minimal space

How customers use the Mtuft Mini

- Presentation of yarn as a piece of carpet

- Product Development

- Colour Development

- Quality Control

- showing faults in yarn

- critical comparisons between 2 yarn packages – colour matching

- effective on space dye yarn

Downloads

Product

Brochure

Technical

Specifications

Reference

List

Request or Create

YOUR OWN SAMPLE

Ask us about the high-quality samples

made on the Mtuft Mini machine.

CALL US ON +61 3 5622 3261

Model(s): TMMS 051, TMMSXL 051

TECHNICAL SPECIFICATIONS:

| Model | TMMS 051 | TMMSXL 051 |

|---|---|---|

| Machine Depth (considering doorway clearance): - With machine assembled - With machine disassembled | Depth: 800 mm (2'7") 860 mm (2'10") | Depth: 850 mm (2'8") 910 mm (3') |

| Machine Height (on supplied wheels) | 1,470 mm (4'10") | 1,470 mm (4'10") |

| Machine width | 2,070 mm (6'9") | 2,070 mm (6'9") |

| Area Required—Width | 2,800 mm (9'2") | 2,800 mm (9'2") |

| Area Required—Depth | 2,800 mm (9'2") | 2,800 mm (9'2") |

| Machine Mass | 470 kg (1,036 lbs) | 470 kg (1,036 lbs) |

| Shipping Crate Dimensions (LWH) | 1,550 x 970 x 1,560 mm (4'11" x 3'2" x 5'1") | 1,550 x 970 x 1,560 mm (4'11" x 3'2" x 5'1") |

| Shipping Mass Total | 600 kg (1,324 lbs) | 600 kg (1,324 lbs) |

| Power Requirements (USA & Japan) | 110v Single Phase 10A | 110v Single Phase 10A |

| Power Requirements (Rest of World) | 220/240v Single Phase 5A | 220/240v Single Phase 5A |

All specifications are subject to change without notice.

Note: Power wiring must include earth.

Machine can be wheeled into position by hand and is set on levelling feet when in position.

More Info

VIDEOS E-BOOKS BLOGS NEWS

Mtuft Mini FAQs

Is it possible for Modra to run trials on the Mtuft Mini machine prior to my purchase?

Yes, we are happy to do this. To arrange for a trial, click here.

What type of primary backing is used?

Yes, we are happy to do this. To arrange for a trial, click here.

Is the Mtuft Mini suitable for artifical turf yarn?

Yes.

What types of construction are possible on the Mtuft Mini?

It is possible to do either cut or loop only.

How fast is the Mtuft Mini machine?

The maximum speed is up to 16 stitches per second.

What product widths are possible on the Mtuft Mini machine?

Up to 500mm wide.

What pile height is possible on the Mtuft Mini machine?

From 3mm to 75mm.

Does Modra have a system for backing Mtuft Mini samples?

Yes, the Modra Sample Backing Press is used to apply a hotmelt backing product to the sample. Modra has a range of backing material available. To find out more, click here.

Is it possible to shear an Mtuft Mini sample?

Yes, this is possible using the Modra Shearing System. To find out more, click here.

What are the power requirements for the Mtuft Mini machine?

For USA & Japan: 110 volts, single phase.

For Rest of World: 220 volts, single phase.

What are the compressed air requirements for the Mtuft Mini machine?

The Mtuft Mini does not require compressed air.

What is the environment and normal operating temperature for the Mtuft Mini machine?

10-40 degrees Celsius, in a clean and dry environment (5-95% humidity, non-condensing).