Introducing

AUTOMATED YARN CREELING SYSTEM

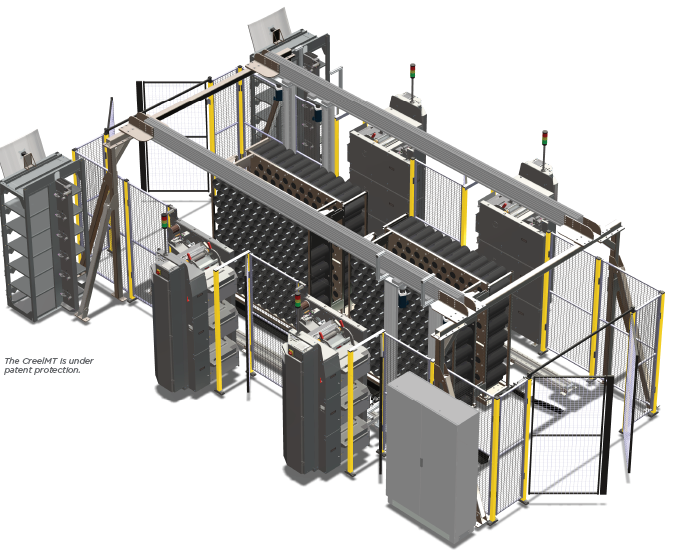

MODRA TECHNOLOGY, innovators in soft flooring solutions, has launched the evolutionary automated yarn creeling system, CreelMT™ for tufted carpet manufacturers.

CreelMT™ IS AN AUTOMATED SYSTEM THAT WINDS YARN TO LENGTH AND USES ROBOTICS TO LOAD THE FULL PACKAGE OF YARN INTO A MOBILE CREEL.

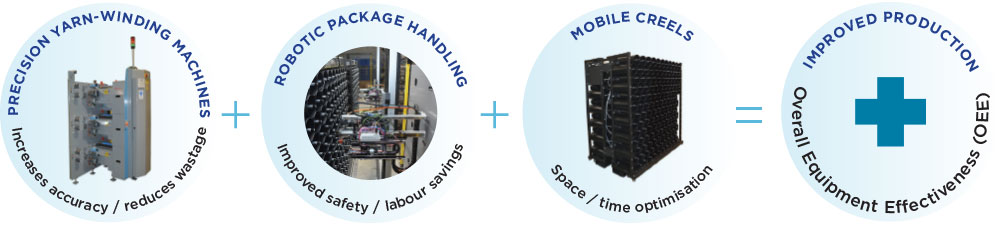

OUR CreelMT™ SYSTEM COMBINES:

CreelMT is unique and in some respects it’s not revolutionary but evolutionary. We’ve drawn together a number of existing technologies – mobile creels, precision winding of yarn, integration with CAD systems and robotics – into one complete system and created an automated, robotic yarn package handling system as a smart alternative to the traditional fixed creel.

Benefits

MAKE SHORTER PRODUCT RUNS MORE ECONOMICALLY

CreelMT™ FEATURES:

-

Suitable for many types of tufting machines

-

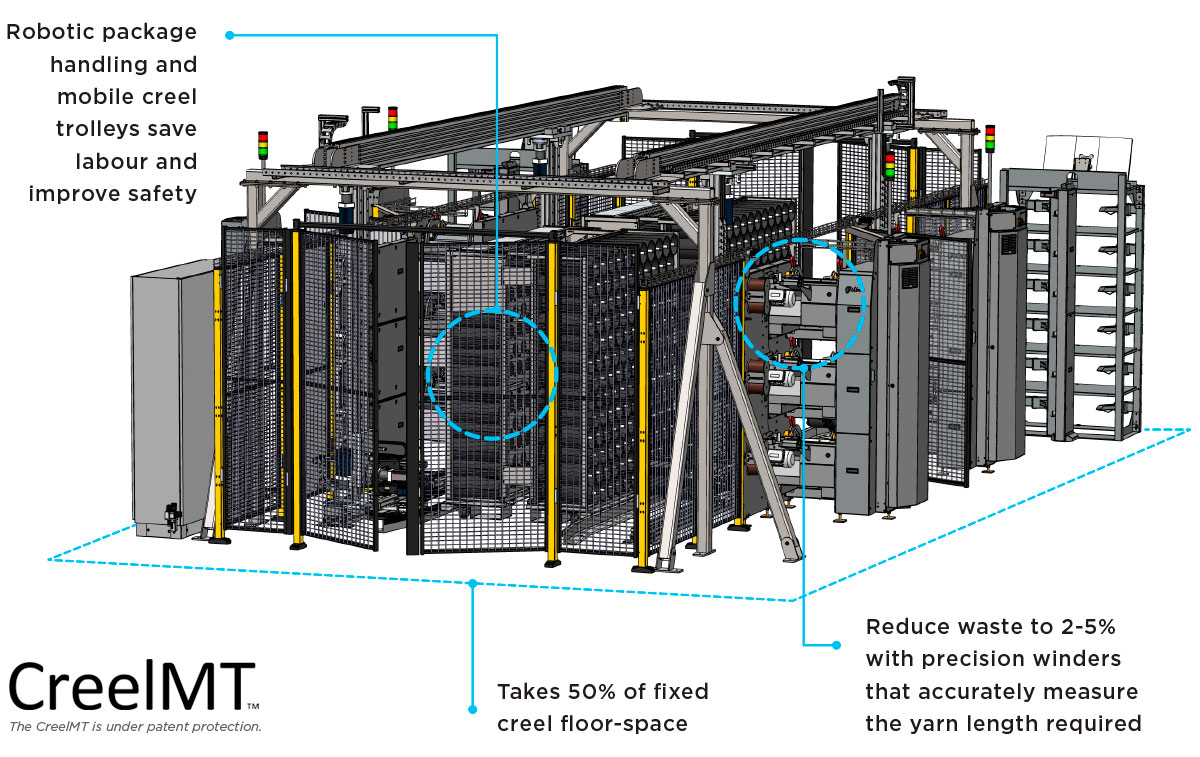

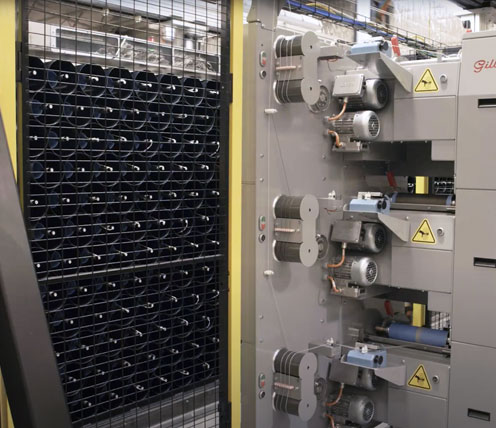

Gilbos precision winders accurately measure yarn length and reduce waste

-

CreelMT™ system configured to meet your needs

-

Automation and robotics to reduce manual handling and improve safety

-

Compact – takes 50% of fixed creel floor-space

CreelMT™ Webinars

Learn more about CreelMT™. Watch Tim Modra’s the two part webinar recording to learn if CreelMT™ is right for your business.

Webinar 1:

Europe time zone + USA time zone options

Introduction to the CreelMT™

Webinar 2:

Europe time zone + USA time zone options

Financial Benefits of the CreelMT™

BOOK A

PRODUCT DEMONSTRATION

Experience the combined impact of an automated yarn creeling system.

CLICK HERE TO REGISTER YOUR INTEREST

MODEL(S): 1R3S, 4R12S, 4R24S,

CreelMT™ TECHNICAL SPECIFICATIONS:

| 1-Robot 3-Spindles (Model: 1R3S) | 4-Robot 12-Spindle (Model: 4R12S) | 4-Robot 24-Spindle (Model: 4R24S) |

|

|---|---|---|---|

| Application | Typically suited as a trial system or for sampling requirements | Will typically keep up with a narrow (~2.0m) tufting machine | Will typically keep up with a broadloom (~4.0m) tufting machine |

| High speed Gilbos Uniwinder | 1 stack of 3 spindles, 3 spindles in total | 4 stacks of 3 spindles, 12 spindles in total | 8 stacks of 3 spindles, 24 spindles in total |

| Nominal winding speed | 800m/min, maximum throughput of 2,400m/min | 800m/min, maximum throughput of 9,600m/min | 800m/min, maximum throughput of 19,200m/min |

| Robotic package handlers | 1 | 4 | 4 |

| Safety cage | Yes | Yes | Yes |

| Dimensions | 2,823 x 5,564 x 2,830mm (WDH) | 5,985 x 9,715 x 2,830mm (WDH) | 8,125 x 9,713 x 2,830mm (WDH) |

| Design format | Microsoft Excel file | ||

| Power Requirements | 400 V 3 Phase with PE, 10 A max | 400 V 3 Phase with PE, 40 A max | 400 V 3 Phase with PE, 60 A max |

| Air Requirements | 57L/min @ 7 bar 2cfm @ 100 psi | 227L/min @ 7 bar 8cfm @ 100 psi | 340L/min @ 7 bar 12cfm @ 100 psi |

| Operating Environment | 10 - 40 degrees Celsius, in a clean and dry environment 5 - 95% humidity non-condensing |

||

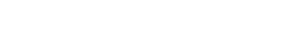

MOBILE CREEL TROLLEY

| 1kg Max Capacity per Position (depending on yarn denier) | 2kg Max Capacity per Position (depending on yarn denier) |

|

|---|---|---|

| Maximum number of positions | 312 | 242 |

| Maximum package diameter | 140mm | 180mm |

| Headers and header strips | To suit customer specification | |

| Dimensions | 2,134 x 1,200 x 2,275mm (WDH) | 2,768 x 1,200 x 2,295mm (WDH) |

| Transport Methods | Creel trolleys can be moved by hand, pallet truck or forklift | |