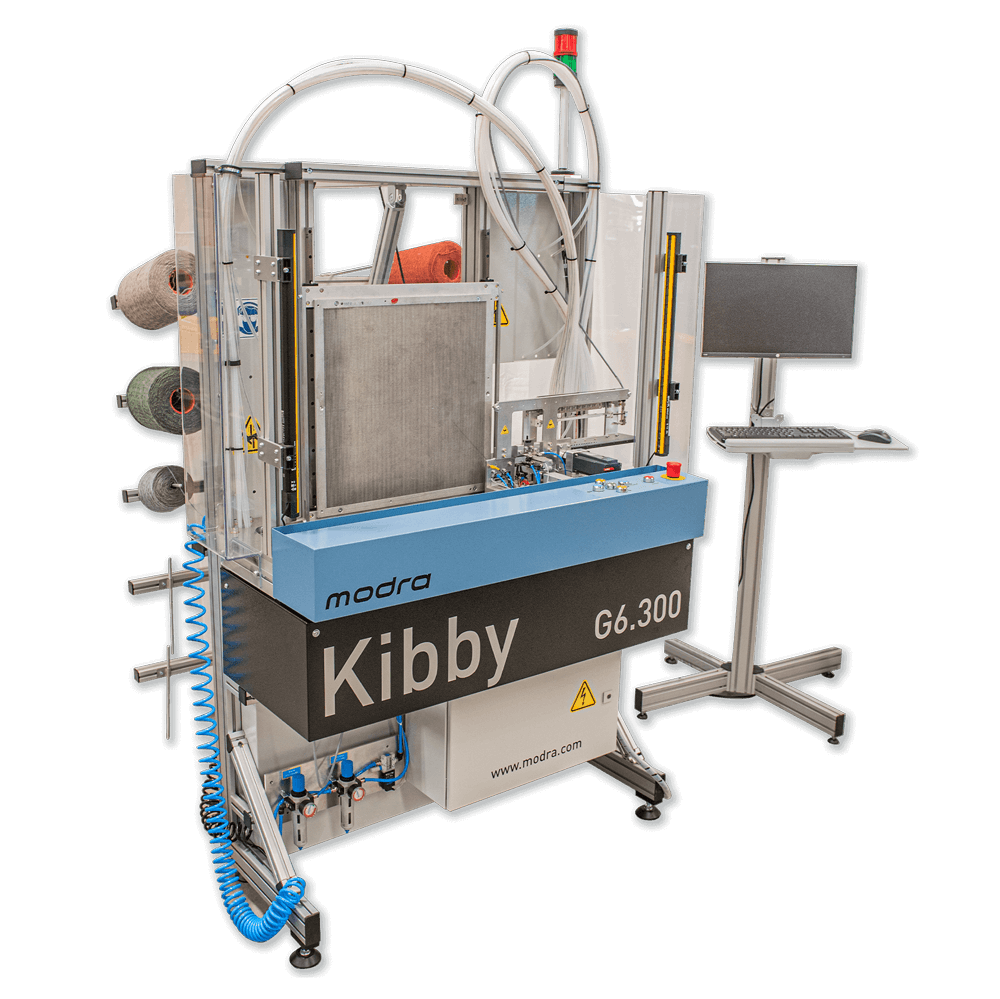

Kibby

The world’s only Axminster carpet sampling machine

Carpet Sample Machine

If you make Axminster/woven or Wilton-style carpet, you need the Kibby. Transform your product development, presentation and marketing by creating full-sized product samples in next to no time. The Modra Kibby allows for almost infinite design and colour possibilities, freeing up your production machines and enabling you to respond to your customers’ needs quickly with high-quality samples.

Features:

- New model (G6) reduced noise level

- New pegboards available for sampling high-density product

- Servo motors for speed and accuracy

- Light curtains for improved safety

- Beckhoff industrial PC running windows 10 with a touch screen

- Kibby can connect to your network for easy pattern loading

- Knot detection system

- Cutter improvements to the G6 machine allow for

- Easier and more precise height adjustment of the cutter

- Better tension control on cutter blades means longer cutter life

- Remove and refit cutter to exactly the same place means no more cutter position “tuning”

- Guide improvements to the G6 machine

- Larger cylinder used on guides means longer life for guide cylinders

- Guide reed switches visible and adjustable from operator view

- Range of needle sizes – 1.0mm, 1.2mm and 1.4mm

“With a single package of yarn, the designer’s creation can be turned into an actual sample quickly and handed directly to the customer.”

Carpet manufacturer, China

Benefits

Free up your production machines and respond to your customers’ needs with high-quality samples

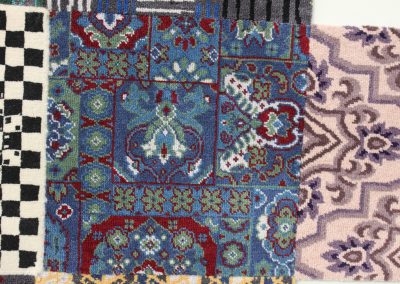

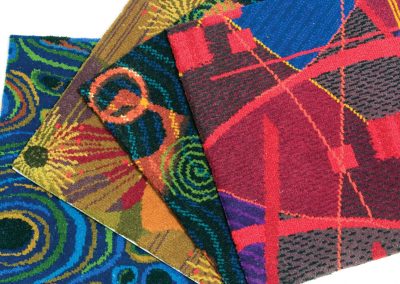

- Axminster, Colortec, Wilton samples all possible on the Kibby machine

- Fast product development – quickly try out designs and see patterns in alternative colourways

- Kibby takes product development away from production machines

- Once set up, the Kibby can run unattended

- Up to 20 colours possible

- Wide range of pegboards for different densities and yarn weights

- Speed of response to customers

How customers use the Kibby

- As a sales tool

- Product development

- Colour development

- Sample for new machines

- Quality control

Downloads

Product

Brochure

Technical

Specifications

Reference

List

Request or Create

YOUR OWN SAMPLE

Ask us about the high-quality samples

made on the Kibby machine.

CALL US ON +61 3 5622 3261

Model(s): G5.200, G6.300

TECHNICAL SPECIFICATIONS:

| Kibby | G5.200 | G6.300 |

|---|---|---|

| Machine Depth (doorway clearance required) - Machine assembled - Machine disassembled | Depth: 1,400 mm / 4’ 7” 570 mm / 1’ 10” | Depth: 1,400 mm / 4’ 7” 570 mm / 1’ 10” |

| Machine Height | 2,200 mm / 7’ 3” | 2,200 mm / 7’ 3” |

| Machine Width | 1,300 mm / 4’ 3” | 1,300 mm / 4’ 3” |

| Area required - Width - Depth | Area required 2,500 mm / 8’ 2” 2,400 mm / 7’ 10” | Area required 2,500 mm / 8’ 2” 2,400 mm / 7’ 10” |

| Machine Mass | 200 kg / 440 lbs | 200 kg / 440 lbs |

| Shipping Crate Dimensions (LxWxH) | 1,990 x 1,420 x 1,090 mm 6’6” x 4’8” x 3’7” | 1,990 x 1,420 x 1,090 mm 6’6” x 4’8” x 3’7” |

| Shipping Total Mass | 350 kg / 770 lbs | 350 kg / 770 lbs |

| Noise Levels (at 1 metre) | 76 dBa | 73 dBa |

| Compressed Air Requirements – dry, clean air | 400 lit/min @ 7 bar 14 cfm @ 100 psi | 600 lit/min @ 7 bar 21 cfm @ 100 psi |

| Power Requirements | 220 / 240 v Single Phase 10 A | 220 / 240 v Single Phase 10 A |

All specifications are subject to change without notice

Note: Power wiring must include earth.

Machine can be wheeled into position by hand and is set on levelling feet when in position.

Machine should be installed in an air-conditioned environment (suitable for PC operation).