One Client Is All It Takes

Why a Sampling Machine is your fastest route to Major Sales If you’re in the business of manufacturing carpets, rugs, […]

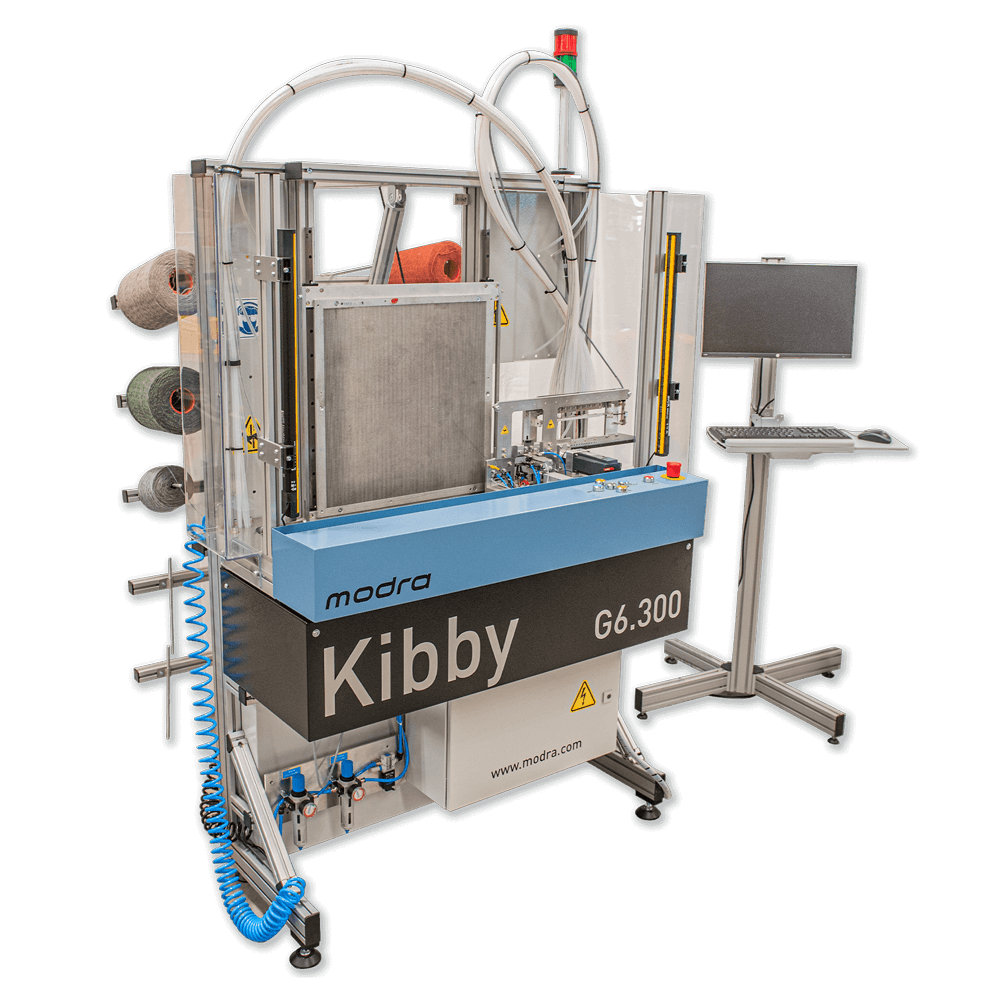

The world’s only Axminster sampling machine

Designed to address the complexity of intricate designs, crisp patterns, high-density weave, and long-term durability requirements, the Kibby machine is a specialised sampling solution uniquely crafted by Modra Technology to meet the demands of Axminster carpets.

Single and double pegboards with a multitude of configurations to reflect and match production quality. Our range of single, double, and high-density pegboards allow for different pile heights and constructions including cut, loop (level), multi-height loop and cut-loop.

Pegboards are available as 4mm, 6mm or 8mm thick boards allow a pile height from 4.5mm to 10mm.

Knot detection systems allow the use of rewound yarn without the risk of machine damage or need to dissemble and clean.

Larger and stronger guide cylinders that last longer, even if the machine is not adjusted correctly.

Larger range of needle sizes from (1.0mm for finer yarns to 1.4mm) for better quality samples.

Multi-turn encoders provide a faster movement on corner set so you can create samples faster than ever before.

Easy and precise cutter height adjustment (1mm per turn) enables a quick and accurate adjustment to the “J” as yarn size or characteristics change.

Improved tension control on the cutter blades lets your blades last longer while reducing downtime.

No more tuning the machine after cleaning, adjusting or replacing a blade with the primary placement cutter location system.

Enhanced safety through additional light curtains to protect the operator.

Design using up to 20 vibrant colours and create endless variations for unlimited creativity.

No calibration is required thanks to the servo motors.

Fast and easy-to-adjust guide cylinders directly designed for operator efficiency.

Up to three decibels quieter than previous models to protect your operators and reduce operator fatigue.

New guided guide set-up tool to assist operators to make very fast alignments of the stripper plate, needle and sets the correct guide gap.

Easy network connection (ethernet, PC networking, USB and internet) to ensure your Kibby G6.300 connects to and remains on your network.

German-made, industrial quality PC with Windows 10 for a long reliable life even in hot, dusty conditions.

Get in touch with us today and choose your preferred starting point.

Videos, E-Books, Blogs & News

Why a Sampling Machine is your fastest route to Major Sales If you’re in the business of manufacturing carpets, rugs, […]

The infographic shows Modra’s impressive growth and widespread adoption amongst companies seeking innovative textile solutions.

The investment that changes everything* David sat across from his CEO, a seasoned industry veteran who had seen every machine, […]