One Client Is All It Takes

Why a Sampling Machine is your fastest route to Major Sales If you’re in the business of manufacturing carpets, rugs, […]

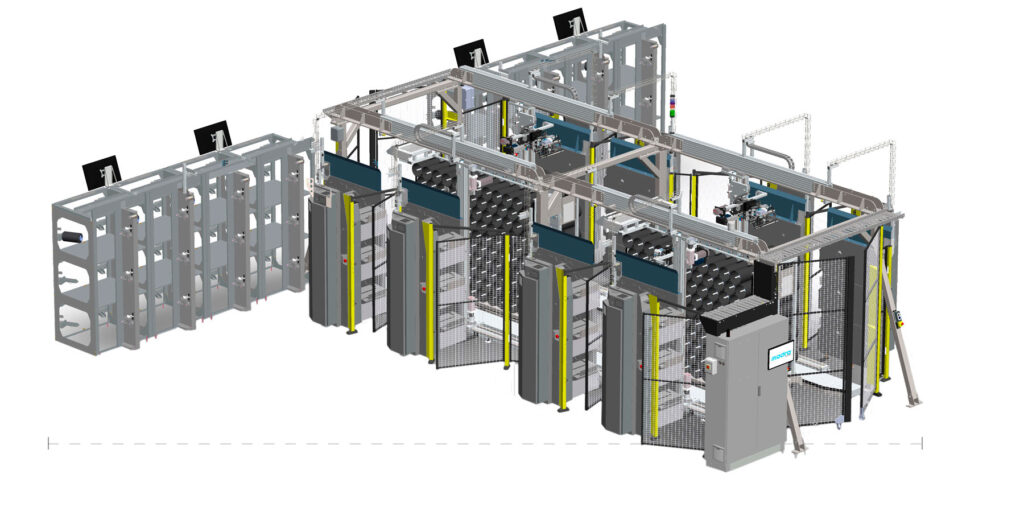

Introducing

Automated yarn creeling system

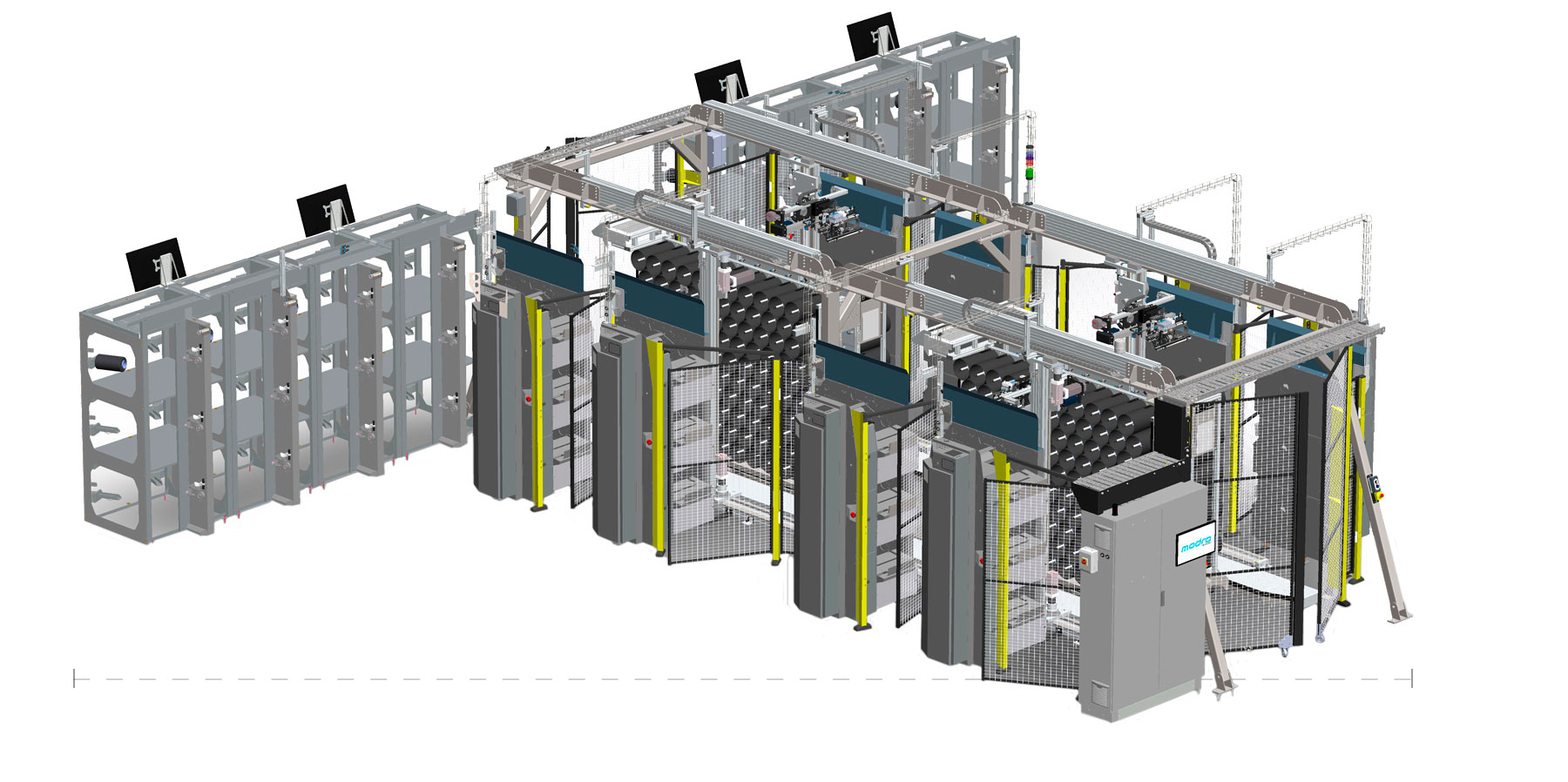

CreelMT is an automated yarn creeling system for tufted carpet machines that winds yarn to the length required for each needle position and uses robotic package handlers to place the yarn package into a mobile creel trolley.

Key data is displayed for the job being run, including a countdown of wound packages and the colour, needle position and yarn length.

Gilbos precision winders accurately measure the yarn length required for each needle position, reducing yarn waste.

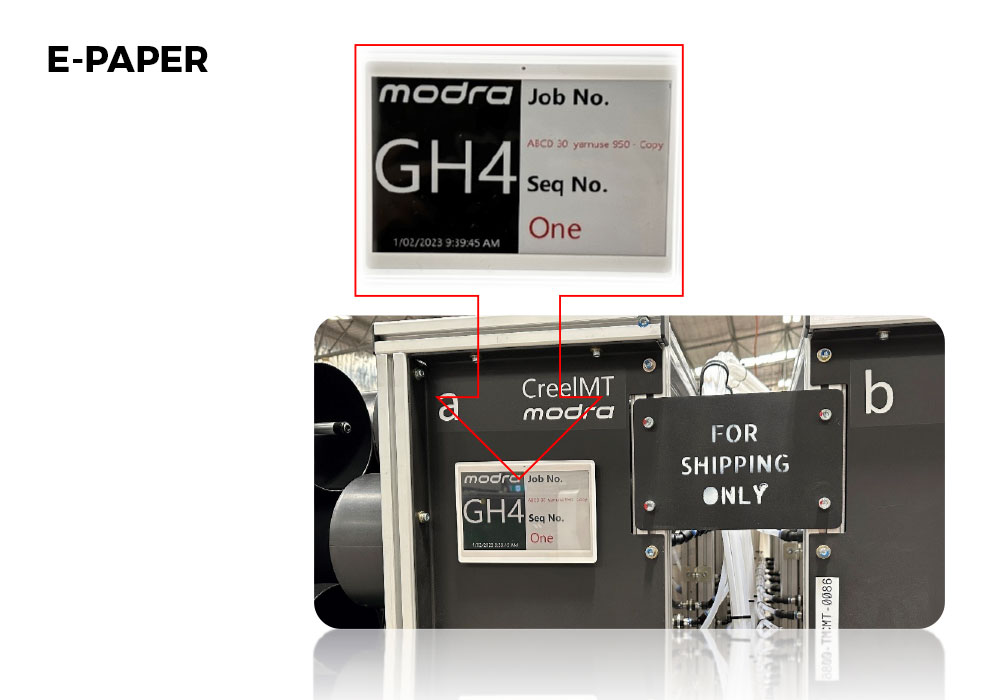

E-Paper is a wireless, electronic label that is fixed to the mobile creel trolley containing information about the job. Information updates automatically as new jobs are loaded into the Creel MT system.

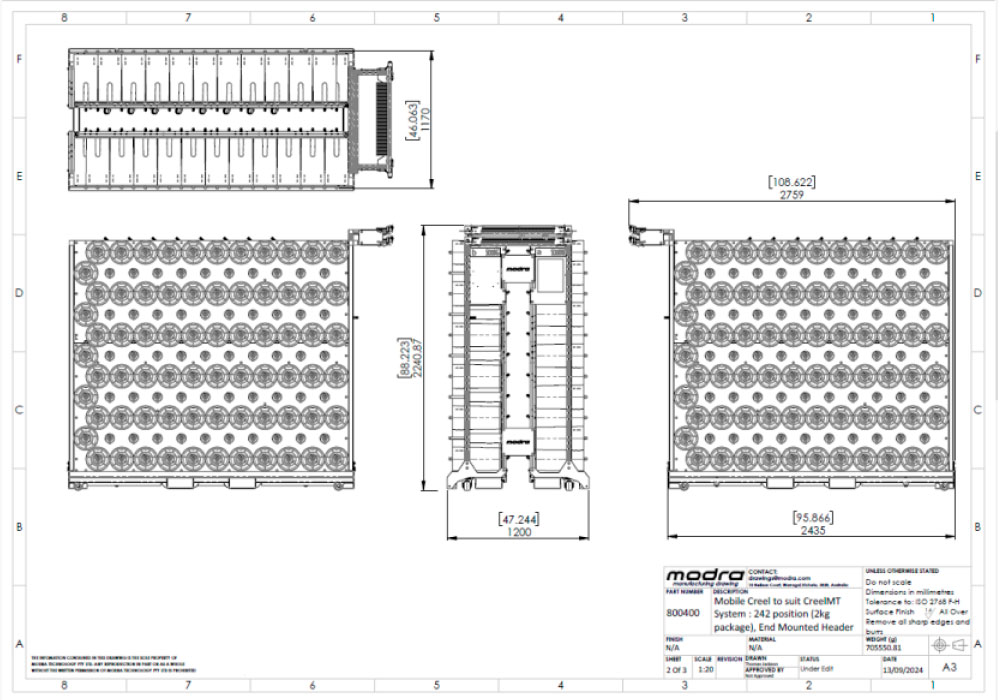

The number of positions in the Mobile Creel Trolley is tailored to suit the maximum number of needle positions in the tufting machine, along with header bar placement and the header strip pitch.

Robotic heads move wound packages of yarn from the winder into the mobile creel trolley, saving labour and improving safety.

Fully enclosed safety cage to protect the operator from any high-velocity moving parts. The system features E-stops on the cage and winders, safety keys on the doors and lockout switches for power and air with a full safety reset process.

Takes up to 50% less floor space than a fixed creel.

Make shorter product runs more economically with CreelMT™

Learn more about CreelMT. Watch Tim Modra’s two-part webinar recording to determine whether it is right for your business.

Experience the impact of an automated yarn creeling system.

WATCH THE CreelMT™ IN ACTION

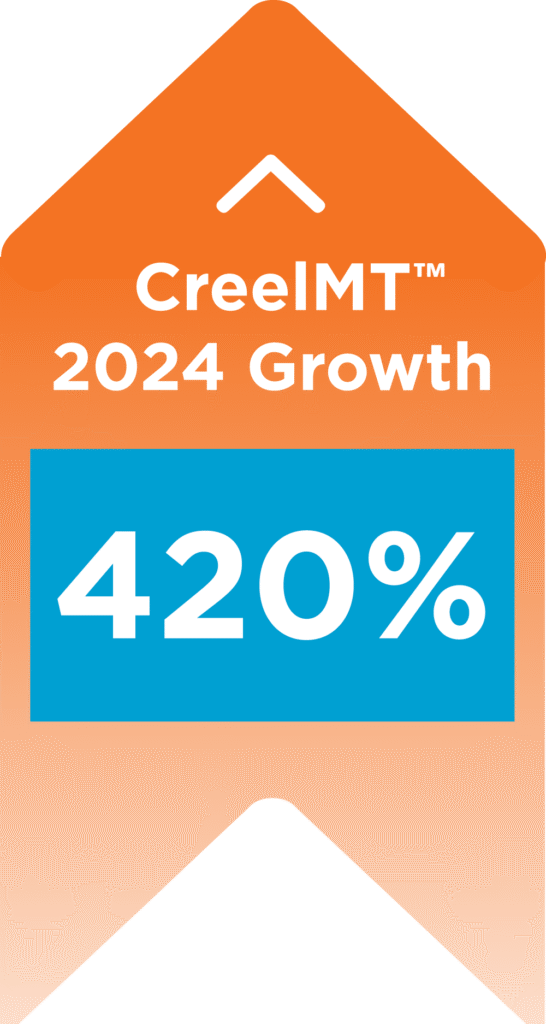

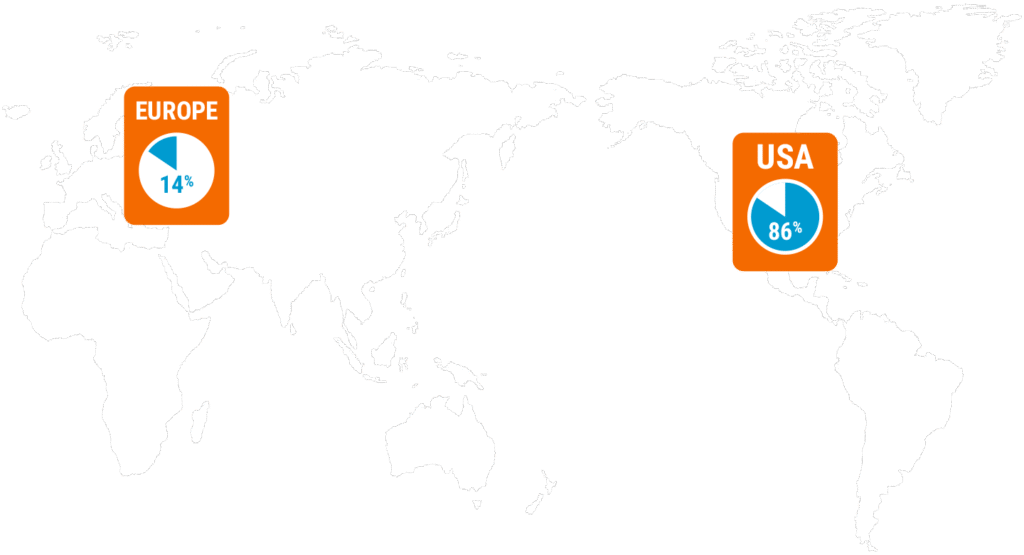

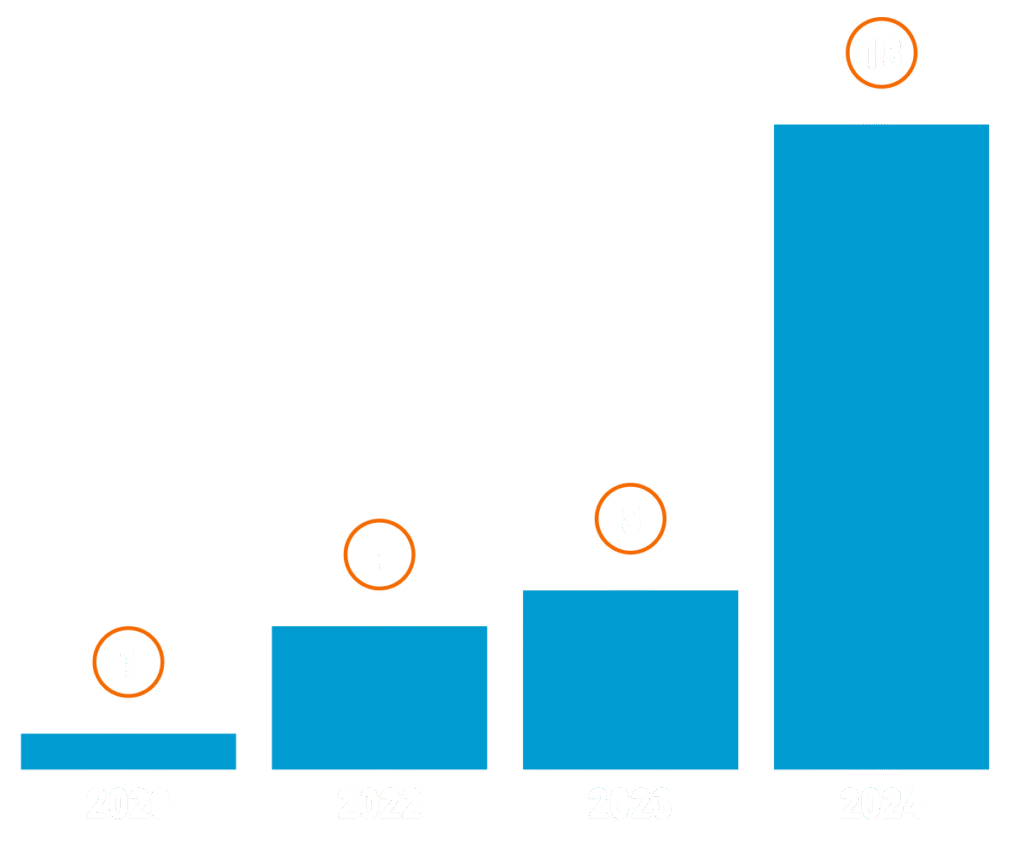

The infographic below shows Modra’s impressive growth and widespread adoption amongst companies seeking innovative textile solutions.

CreelMT™ proven results, 28 machines sold by the end of 2024

MODEL(S): 1R3S, 4R12S, 4R24S,

| 1-Robot 3-Spindles (Model: 1R3S) | 4-Robot 12-Spindle (Model: 4R12S) | 4-Robot 24-Spindle (Model: 4R24S) |

|

|---|---|---|---|

| High speed Gilbos Uniwinder | 1 stack of 3 spindles, 3 spindles in total | 4 stacks of 3 spindles, 12 spindles in total | 8 stacks of 3 spindles, 24 spindles in total |

| Nominal winding speed | 800m/min, maximum throughput of 2,400m/min | 800m/min, maximum throughput of 9,600m/min | 800m/min, maximum throughput of 19,200m/min |

| Robotic package handlers | 1 | 4 | 4 |

| Safety cage | Yes | Yes | Yes |

| Design format | Microsoft Excel file | ||

| Power Requirements | 400 V 3 Phase with PE, 10 A max | 400 V 3 Phase with PE, 40 A max | 400 V 3 Phase with PE, 60 A max |

| Air Requirements | 57L/min @ 7 bar 2cfm @ 100 psi | 227L/min @ 7 bar 8cfm @ 100 psi | 340L/min @ 7 bar 12cfm @ 100 psi |

| Operating Environment | 10 - 40 degrees Celsius, in a clean and dry environment 5 - 95% humidity non-condensing |

||

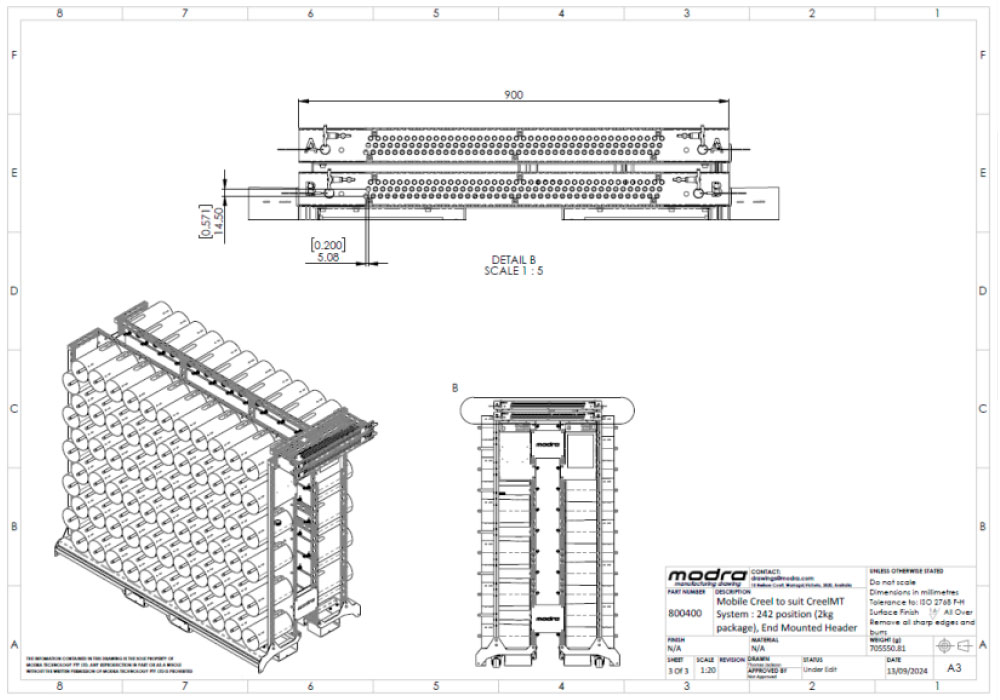

Mobile Creel Trolley

| 1kg Max Capacity per Position (depending on yarn denier) | 2kg Max Capacity per Position (depending on yarn denier) |

|

|---|---|---|

| Maximum number of positions | 312 | 264 |

| Maximum package diameter | 140mm | 180mm |

| Headers and header strips | To suit customer specification | |

| Transport Methods | Creel trolleys can be moved by hand, electric pallet jack or forklift | |

E-Paper & Mobile Creel Trolley

Gilbos Winder Creel Options

Winder Creel 2 x 6

“2” = packages per spindle

“6” = spindles fed per creel frame

Note: Supplied as standard

Winder Creel 4 x 3

“4” = packages per spindle

“3” = spindles fed per creel frame

Note: Supplied at additional charge

Winder Creel 4 x 2

“4” = packages per spindle

“2” = spindles fed per creel frame

Note: Supplied at additional charge

“I saw the application of the CreelMT™ in our process as a game changer to improve our efficiencies. Tufting downtime due to changeover, reduction in creeler hours, yarn material handling and yarn waste. We’ve improved our tufting capacity, on the machines serviced by the CreelMT™, by more than 100%.”

Doug Schneller, Vice President – Manufacturing Engineered Floors LLC

Why a Sampling Machine is your fastest route to Major Sales If you’re in the business of manufacturing carpets, rugs, […]

The infographic shows Modra’s impressive growth and widespread adoption amongst companies seeking innovative textile solutions.

The investment that changes everything* David sat across from his CEO, a seasoned industry veteran who had seen every machine, […]